Whether indoors or outdoors, proper wire and cable installation is of paramount importance - ensuring a smooth electricity supply, as well as passing electrical inspections. Each wire and cable needs to be installed carefully, from the fuse box to the outlets, fixtures and appliances. The National Electrical Code (NEC) and Local Building Codes regulate the manner of installation and the types of wires and cables for various electrical applications.

Understanding Electrical Wire

Image Source: joelynchelectrical.com

Some factors that will affect your choice of electrical wiring include color, label information and applications. The information printed on the electrical wire covering is all that you need to choose the correct wire for your home. Here’s some detailed information on the various features of electrical wire, which will help you choose the correct composition:

1. Size of Wires

Each application requires a certain wire size for installation, and the right size for a specific application is determined by the wire gauge. Sizing of wire is done by the American wire gauge system. Common wire sizes are 10, 12 and 14 – a higher number means a smaller wire size, and affects the amount of power it can carry. For example, a low-voltage lamp cord with 10 Amps will require 18-gauge wire, while service panels or subpanels with 100 Amps will require 2-gauge wire.

2. Wire Lettering

The letters THHN, THWN, THW and XHHN represent the main insulation types of individual wires. These letters depict the following NEC requirements:.

- T – Thermoplastic insulation

- H – Heat resistance

- HH – High heat resistance (up to 194°F)

- W – Suitable for wet locations

- N – Nylon coating, resistant to damage by oil or gas

- X – Synthetic polymer that is flame-resistant

3. Types of Electrical Wire

There are mainly 5 types of wire: .

- Triplex Wires : Triplex wires are usually used in single-phase service drop conductors, between the power pole and weather heads. They are composed of two insulated aluminum wires wrapped with a third bare wire which is used as a common neutral. The neutral is usually of a smaller gauge and grounded at both the electric meter and the transformer.

- Main Feeder Wires : Main power feeder wires are the wires that connect the service weather head to the house. They’re made with stranded or solid THHN wire and the cable installed is 25% more than the load required.

- Panel Feed Wires : Panel feed cables are generally black insulated THHN wire. These are used to power the main junction box and the circuit breaker panels. Just like main power feeder wires, the cables should be rated for 25% more than the actual load.

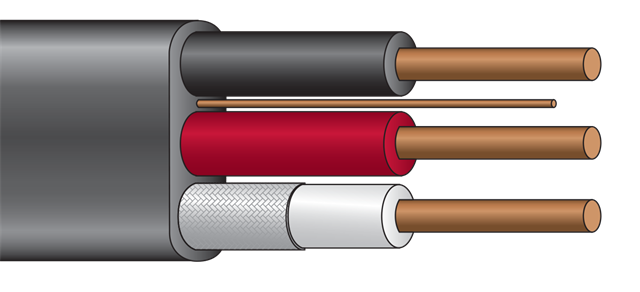

- Non-Metallic Sheathed Wires : Non-metallic sheath wire, or Romex, is used in most homes and has 2-3 conductors, each with plastic insulation, and a bare ground wire. The individual wires are covered with another layer of non-metallic sheathing. Since it’s relatively cheaper and available in ratings for 15, 20 and 20 amps, this type is preferred for in-house wiring.

- Single Strand Wires : Single strand wire also uses THHN wire, though there are other variants. Each wire is separate and multiple wires can be drawn together through a pipe easily. Single strand wires are the most popular choice for layouts that use pipes to contain wires.

4. Color Codes

Different color wires serve different purposes, like:.

- Black : Hot wire, for switches or outlets.

- Red : Hot wire, for switch legs. Also for connecting wire between 2 hardwired smoke detectors.

- Blue and Yellow : Hot wires, pulled in conduit. Blue for 3-4 way switch application, and yellow for switch legs to control fan, lights etc.

- White : Always neutral.

- Green and Bare Copper : Only for grounding.

5. Wire Gauge, Ampacity and Wattage Load

To determine the correct wire, it is important to understand what ampacity and wattage a wire can carry per gauge. Wire gauge is the size of the wire, ampacity is how much electricity can flow through the wire and wattage is the load a wire can take, which is always mentioned on the appliances..

Wire Types + Uses . Video by Neepawa GG

Understanding Electrical Cable

An electrical cable also has different types, color and application as its determining factors. Here’s a brief about cables that you need to understand to determine the correct cable for your home.

1. Types of Electrical Cables

There are more than 20 different types of cables available today, designed for applications ranging from transmission to heavy industrial use. Some of the most commonly-used ones include:

- Non-Metallic Sheathed Cable : These cables are also known as non-metallic building wire or NM cables. They feature a flexible plastic jacket with two to four wires (TECK cables are covered with thermoplastic insulation) and a bare wire for grounding. Special varieties of this cable are used for underground or outdoor use, but NM-B and NM-C non-metallic sheathed cables are the most common form of indoor residential cabling.

- Underground Feeder Cable : These cables are quite similar to NM cables, but instead of each wire being individually wrapped in thermoplastic, wires are grouped together and embedded in the flexible material. Available in a variety of gauge sizes, UF cables are often used for outdoor lighting and in-ground applications. Their high water-resistance makes them ideal for damp areas like gardens as well as open-to-air lamps, pumps, etc.

2. Cable Color Code

Color coding of cable insulation is done to determine active, neutral and earth conductors. The NEC has not prescribed any color for phase/active conductors. Different countries/regions have different cable color coding, and it is essential to know what is applicable in your region. However, active conductors cannot be green/yellow, green, yellow, light blue or black..

3. Cable Size

Cable size is the gauge of individual wires within the cable, such as 14, 12, 10 etc. – again, the bigger the number, the smaller the size. The number of wires follows the wire-gauge on a cable. So, 10/3 would indicate the presence of 3 wires of 10-gauge within the cable. Ground wire, if present, is not indicated by this number, and is represented by the letter ‘G’.

Safety is very important, and if your installation of wires and cables is not proper, it could lead to accidents. Before you start any electrical project that includes wiring and cabling, you need to obtain permission from your local building inspector. Once the job is done, get the installation inspected for compliance with local codes and regulations.

FAQs

1. What is a standard wire?

A standard wire is made of multiple thin strands that are majorly made of copper. These strands are twisted and combined in a PVC cable to create a multi-strand of a conductor.

2. How to connect stranded wire to solid wire?

You can connect a stranded wire to a solid wire with wire nuts by following the below process:

- To begin, keep the exposed stranded wire longer than the solid wire by removing the insulation from both wires

- The next step is to wrap the stranded wire with the solid wire

- Next, secure the twisted wires by twisting an appropriately sized wire nut over them

- Finally, conduct a pull test on the twisted wires so you are assured that they are securely fastened and not at risk of coming loose

3. Can ethernet cable run next to electrical?

It’s simple to run an ethernet cable next to an electrical cable, but it is not recommended because the chances of interference increase. Since the ethernet cable has a low voltage for data transfer, it produces a magnetic field required for transmitting and receiving data. The high-voltage of the electrical cable can interfere with the magnetic field of the ethernet’s cable when they are placed parallel.

4. Do coaxial cables carry electricity?

Electrical signals flow through a coaxial cable with an inner conductor. This conductor is typically made of stranded, solid, or copper-plated steel wire which is enveloped by an insulating layer that is shielded by almost one to four of metallic tape and woven metallic braid layers. An outer insulating jacket provides safety because the shield’s exterior is maintained in the standard setup, while the center conductor carries the signal’s voltage.

5. How to trace electrical wires?

With the help of a Magnetic Stud Finder, locating hidden wires behind walls, ceilings, or floors becomes a breeze. This handy tool generates electrical fields when placed on a surface, emitting a distinct beep to pinpoint the exact location of the wire. Whether you’re a DIY enthusiast or a professional electrician, this device ensures efficient wire detection without any hassle.

6. What is a common electrical wire?

The common wire, called C-wire or neutral wire, is crucial to your heating system. It completes the circuit initiated by the hot wire, allowing electricity to flow smoothly. This wire extends from the low-voltage heating system, providing a steady power supply to the thermostat. Thermostats, however, detect temperature changes and regulate them in enclosed spaces. With continuous power from the common wire, thermostats effectively maintain a consistent temperature, ensuring comfort and control in your heating system.

7. How to test electrical wires?

Utilizing a voltage tester or a current checker is a straightforward method to determine if a wire is carrying electrical current. These user-friendly devices allow you to effortlessly touch them to any wire, instantly indicating their live status. Moreover, enhanced models of these tools provide additional information, such as precise current measurements and other relevant data. These devices are invaluable for ensuring safety and efficiently working with electrical systems.

8. How to solder electrical wires?

Here’s how you can solder electrical wires:

- Strip the wires and add heat shrink tubing to it

- Join the wires and position them in a way they are elevated on the surface

- Add a small amount of rosin flux to cover the copper

- Solder the wire

- Shrink the tubing

9. Can I use electrical tape to cover an exposed wire?

Certainly, electrical tape serves as a reliable solution for covering and safeguarding exposed wires. However, it is crucial to emphasize the significance of proper application to mitigate any potential safety risks. By carefully adhering to the tape in the correct manner, you can effectively shield the wire, promoting a secure and protected electrical environment.

10. Why is copper used to make electrical cables and wires?

Copper stands out as the ultimate choice for electrical conductors in building wire systems. It boasts unparalleled efficiency, remarkable strength, and unmatched reliability, making it the prime metal for the job. Not only does copper deliver outstanding performance, but it also proves to be the most cost-effective conductor over the entire lifespan of your system. Rest assured, investing in copper ensures optimal conductivity and long-term value for your electrical needs.