Table of Contents

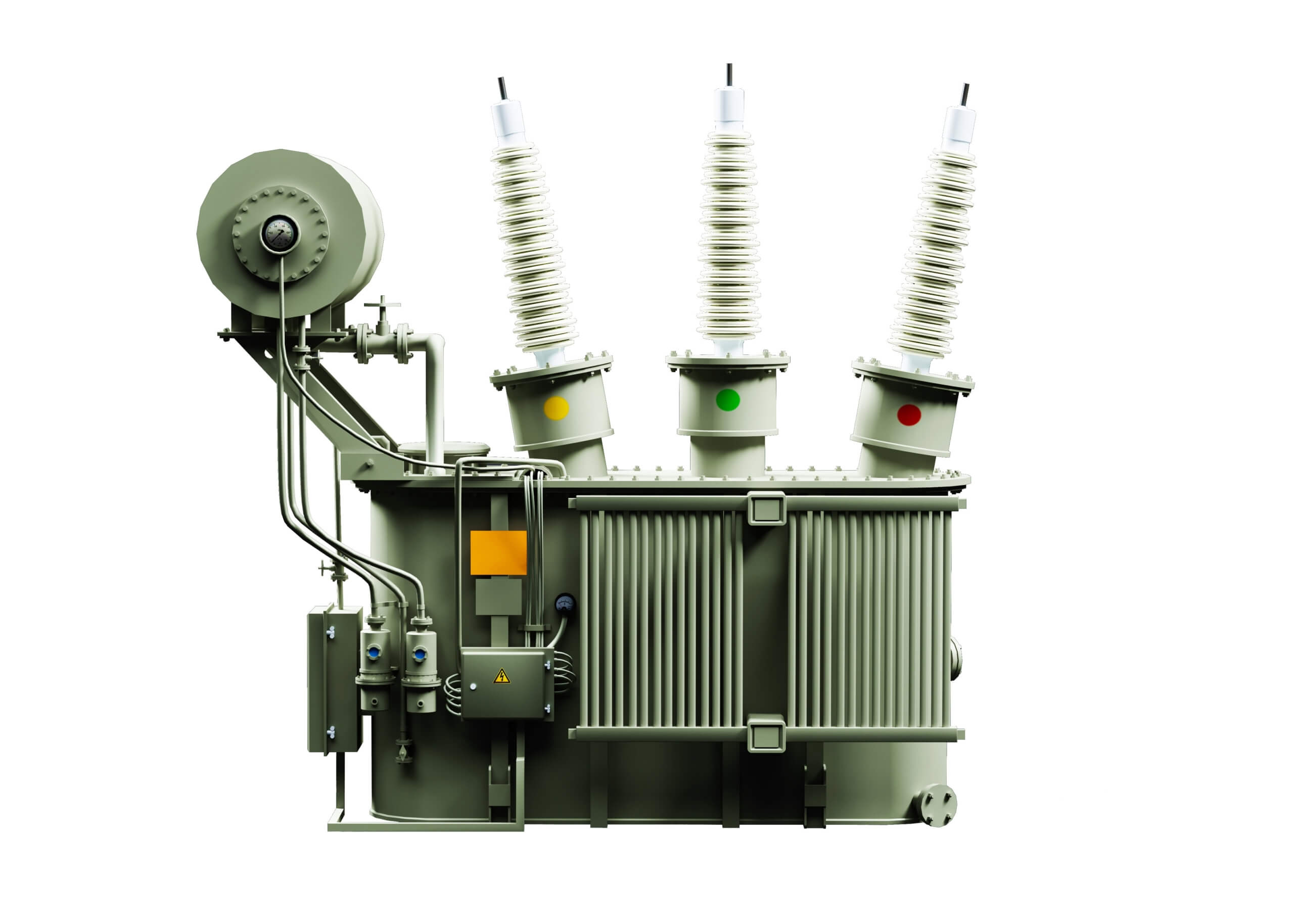

Transformers play a crucial role in today’s electrical infrastructure, facilitating the efficient transmission of electricity from power plants to residential and commercial properties. Regardless of whether you are a homeowner, do-it-yourself enthusiast, tenant, or student, gaining a thorough understanding of transformer components can foster a deeper appreciation for the intricate nature of electrical distribution. Additionally, this knowledge can also empower you to prioritize safety and implement effective maintenance practices.

What is a Transformer?

A transformer is a crucial electrical device that plays a key role in transferring electrical energy between different circuits. It achieves this through the phenomenon of electromagnetic induction. The primary components of a transformer are the core and windings. This device is integral in adjusting voltage levels, allowing for the increase (step-up) or decrease (step-down) of voltage between circuits according to specific requirements. In the realm of power distribution, transformers are instrumental in facilitating the efficient transmission of electricity over long distances. Additionally, they are essential for modifying voltage levels to suit the varied needs of different applications.

Types of Transformers

Transformers come in various types based on core structure, voltage conversion, purpose, windings, insulation, and the number of phases. These variations serve specific purposes and applications:

- Core Type: Laminated, amorphous, and toroidal cores.

- Voltage Conversion: Step-up and step-down transformers.

- Purpose: Power transformers, distribution transformers, and isolation transformers.

- Windings: Autotransformers and double-wound transformers.

- Insulation: Dry-type and oil-immersed transformers.

- Phases: Single-phase and three-phase transformers.

The internal structure of a transformer can differ based on various factors such as its classification, physical dimensions, and intended usage. However, at its core, every transformer consists of essential components like the core and windings. Additional elements such as cooling systems, protective relays, or tap changers are integrated into the design as per the specific operational needs of the transformer.

Components of a Transformer

1. Core

The core of a transformer is constructed using multiple layers of steel sheets, which create a route for the magnetic flux to travel. This design helps to reduce energy losses and is essential for ensuring the transformer operates with high efficiency.

2. Winding

The windings in a transformer are made of insulated copper or aluminum conductors that are wound around the core. The primary winding is where the input voltage is applied, and the secondary winding is where the transformed voltage is produced. The ratio of the number of turns in the primary winding to the number of turns in the secondary winding determines how the voltage is converted.

3. Insulating Material

Insulating materials, such as paper, oil, or epoxy resin, are used in transformers to create a barrier that prevents electrical contact between different components. They also provide protection against electrical breakdown, ensuring the safe and efficient operation of the transformer.

4. Transformer Oil

In oil-immersed transformers, a type of oil known as transformer oil serves two important purposes. Firstly, it acts as an insulator, preventing electricity from escaping and causing malfunctions. Secondly, it functions as a coolant, helping to dissipate heat generated during the transformer’s operation and thus preventing overheating.

5. Conservator

The conservator is a cylindrical tank connected to the transformer, allowing for the expansion and contraction of transformer oil due to temperature changes.

6. Breather

The breather is responsible for extracting moisture from the air that enters the conservator. This helps to safeguard the transformer oil from getting contaminated by moisture.

7. Tap Changer

The tap changer plays a critical role in regulating the voltage of the transformer by modifying the turns ratio in the winding, thereby enabling precise regulation of the output voltage.

8. Bushing

Bushings play a crucial role in transformers by providing insulation and support for the electrical conductors as they enter and exit the transformer casing. They create a safe pathway for the current to flow in and out of the transformer, ensuring efficient and safe electrical operation.

9. Cooling Tubes / Radiator & Fans

Cooling tubes, radiators, and fans dissipate the heat generated by the transformer, which is essential for maintaining its efficiency and longevity.

10. Buchholz Relay

The Buchholz relay is a safety device used in oil-filled transformers. It detects gas accumulation caused by internal faults and triggers an alarm or shuts down the transformer to prevent damage.

11. Explosion Vent

The explosion vent is designed to release pressure in case of an internal fault, thereby preventing the transformer from exploding.

12. Drain Vent

The drain vent allows for the removal of transformer oil for maintenance or replacement.

13. Oil Temperature Gauge

The oil temperature gauge monitors the transformer’s oil temperature, helping detect overheating and potential issues early.

Understanding the different parts of a transformer is vital for the proper functioning of electrical systems and for maintaining safety standards. Regular inspections and maintenance are key to ensuring transformers remain in top working condition. Always keep in mind that electrical work can be dangerous. If you have any doubts about a particular task, prioritize safety and seek assistance from a qualified electrician.

Frequently Asked Questions

1. What are the two main parts of a transformer?

Transformers consist of a core and windings. The core, typically made of laminated steel, provides a path for magnetic flux. Windings are insulated conductors wrapped around the core. The primary winding receives the input voltage, while the secondary winding outputs a voltage based on the turn ratio.

2. Do the components of transformers change in different types of transformers?

The core components (core and windings) are fundamental for all transformers. The presence and type of additional components, such as cooling systems, protective relays, or tap changers, vary depending on the specific type of transformer, its size, and its intended application.

3. What are the different types of transformer cores?

- Laminated Steel Core: The most common and cost-effective option, it minimizes eddy current losses.

- Amorphous Metal Core: Offers higher efficiency but comes at a higher cost.

- Toroidal Core: Compact design but suffers from lower efficiency.

4. Do all transformers have the same components?

No. The specific components required for transformers vary depending on their type and size. Larger power transformers used for high-voltage transmission typically need transformer oil and advanced cooling systems, while smaller distribution transformers might only need simpler cooling methods.

5. What happens if a transformer component fails?

Regular monitoring and maintenance are essential to ensure the efficient and safe operation of transformers. Failing components can result in overheating, diminished performance, and even total transformer failure. Thus, it is crucial to conduct regular inspections to ensure that all transformer components are functioning properly.