Table of Contents

Choosing the proper type of electrical wire for your electrical systems can have a considerable impact on their efficiency, safety, and lifetime. The two most common wires you must’ve heard about are Stranded and solid wire. Each type has its own set of pros and cons.

So understanding the differences between stranded wire and solid wire is critical for making an informed decision for your individual needs. This blog post is here to look at both these choices closely, as well as the instances for which each one is most suited.

What is a Stranded Wire?

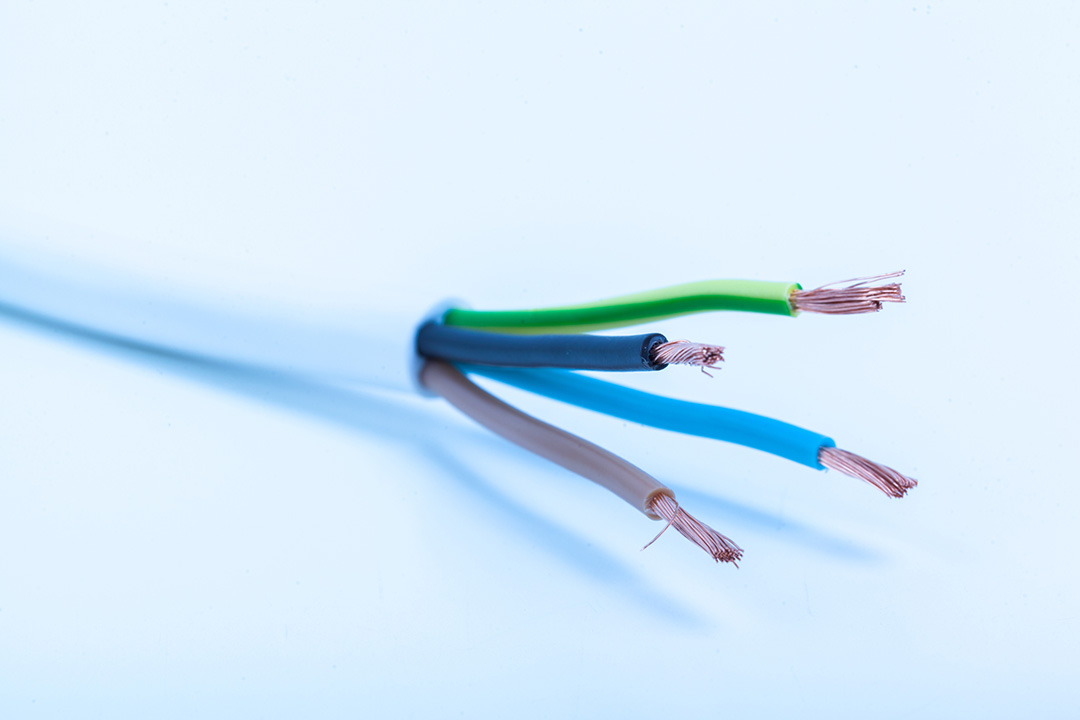

Stranded wire is made up of several thin wires twisted together to produce a flexible bundle. This design makes stranded wire far more malleable than solid wire. Stranded wires are often used in applications requiring frequent movement, such as automotive wiring, circuit boards, and electronic gadgets.

What is a Solid Wire?

Solid wire is made out of a single, solid metal core, which is commonly copper, aluminum, or another conductive substance. This design produces a strong and durable wire, which is commonly utilized in fixed installations.

Differences Between Stranded Wire and Solid Wire

To further understand how stranded and solid wires differ, consider the following criteria:

- Application: Stranded wire is commonly used in automotive wiring, portable electronics, and other applications that require flexibility. Solid wire is best suited for permanent installations such as building infrastructure, outdoor applications, and electrical control systems.

- Cost: Stranded wire is typically more expensive due to its sophisticated manufacturing process. Whereas, solid wire is usually more affordable, making it a cost-effective option for many projects.

- Corrosion: Stranded wire is more prone to corrosion because of the numerous exposed strands. On the other hand, solid wire is generally more corrosion-resistant because of its single-core structure.

- Ampacity: Stranded wire has a lower ampacity due to increased resistance from twisting and junctions between the strands. However, solid wires have a higher ampacity. It allows them to carry more current without overheating.

- Skin Effect: Stranded Wire is more susceptible to the skin effect, which causes current to flow down the wire’s surface, thereby increasing resistance. In contrast, solid wire is less influenced by the skin effect, resulting in more efficient current flow, particularly at higher frequencies.

- Voltage Drop: Stranded wires have a higher voltage drop over longer distances due to greater resistance. Solid wire has a lower voltage drop which allows for more efficient power transmission over greater distances.

- Current Flow: Stranded wire is effective for lower current flows, although it can handle intermediate current levels due to the greater surface area of individual strands. Solid wire is ideal for high-current applications due to its solid nature.

- Flexibility: Stranded wire is highly flexible and appropriate for applications requiring frequent movement. On the contrary, solid wire is rigid and less flexible, making it more suitable for fixed applications.

- Motion Concerns: Stranded wire is intended for use in applications that need motion. Solid wire is best suited for stationary installations with low movement.

- Distance: Stranded wire is ideal for short distances, particularly in applications where flexibility is critical. Conversely, solid wire is ideal for long distances where significant current flow is required.

- Performance: Stranded wire is suitable for movement-based applications. However, corrosion might cause performance concerns. Solid wire provides dependable performance in stationary applications, particularly when resistance to weather and corrosion is critical.

Stranded vs Solid Wire- Comparison Table

Here’s a quick recap!

| Criteria | Stranded Wire | Solid Wire |

| Flexibility | High | Low |

| Current flow | Moderate | High |

| Corrosion | More susceptible | More resistant |

| Ampacity | Lower | Higher |

| Application | Automotive, electronics | Building, outdoor, heavy-duty |

| Voltage drop | Greater | Lower |

| Motion concerns | Designed for movement | Best for stationary applications |

| Performance | Good for flexible applications | Excellent for fixed applications |

| Skin Effect | More | Less |

| Distance | Short distances | Long distances |

| Cost | Higher | Lower |

In essence, the decision between stranded and solid wire is mostly dependent on the unique requirements of your project. Solid wire has higher conductivity and is more cost-effective for shorter installations under 10 meters. Thus, it’s an excellent alternative for projects requiring durability.

Stranded wire, on the other hand, is better suited to dynamic settings since it is more resilient and break-resistant.

As you begin your DIY projects or professional electrical installations, make sure to explore the many characteristics and benefits of each wire type. Be informed, and choose wisely to achieve the best results for your electrical needs.

Looking to enhance the safety of your home? D&F Liquidators offers a complete range of electrical supplies essential for grounding projects, including wires and outlets.

Frequently Asked Questions (FAQs)

How can you determine whether a wire is solid or stranded?

Visual inspection can reveal whether a wire is solid or stranded. Solid wire is comprised of a single piece of metal, whereas stranded wire is made up of numerous smaller strands intertwined together.

Which conducts electricity better: solid or stranded wire?

Solid wire is often more conductive than stranded wire due to its continuous surface area and lower resistance.

Is stranded wire more expensive than solid?

Stranded wires are generally more expensive than solid wires because they provide better flexibility and installation convenience for a wide range of applications.