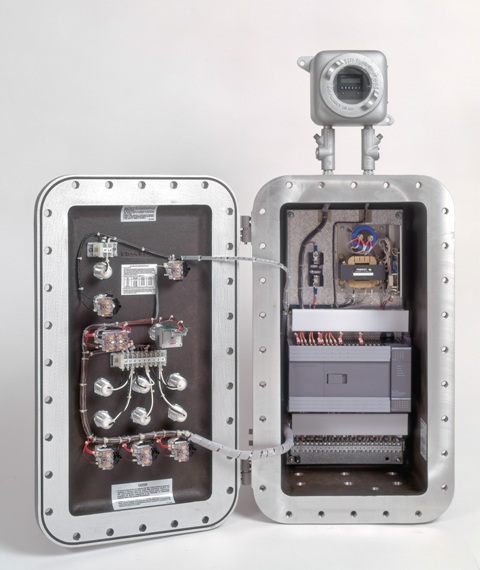

Electric housing or electric enclosures are structures built to protect circuit boards from the elements so they can function properly. Wind, water, dust, debris, cold and humidity are all elements that could damage or interfere with proper working of the circuit board. Your choice of circuit boards is very important since it impacts the functioning of the circuit board over the long haul.

Below are six important factors to consider when selecting your enclosure:

1. Environment

It’s important to know the most common potential environmental threats to decide which enclosures are best suited to protect your circuit boards. You should ask the following.

- What are the prevalent environmental conditions?

- Which is the most important environmental concern?

- What are the extremes in temperature and humidity?

Knowing this, you will be able to determine which enclosure offers maximum protection from elemental factors.

2. Application

The application is concerned with the product or market. Market application considerations include factoring in food plants, repair shops, arena, pools, parking garages and water treatment plants, among others; i.e. where the enclosure is intended to fit. Product applications relate to the requirements of the physical enclosure e.g. duct mounts, ease of access, wall mounts, etc.

3. Thermal management requirements

Managing the buildup from heat generated within the circuit board is essential to ensuring longevity, efficiency and extended lifespan of your products. It is vital therefore to plan for effective thermal management solutions, whether this is to reduce or increase heat to maintain optimal conditions for proper functioning.

4. Performance standards

Understanding enclosure ratings is important so that you can ascertain the level of protection offered by each enclosure. These settings have been standardized throughout the country providing appropriate ratings for locations considered hazardous or non-hazardous. For hazardous locations, further description is provided to separate them into divisions, classes and groups, including the potential of accumulation of hazardous material in the environment.

5. Material

These threats should be considered when selecting the right material for the enclosure, as well as the application location. Materials used may be metallic e.g. aluminum and steel or non-metallic e.g. fiberglass and plastic. The choices to be made depend on the application performance demands i.e. standard, airtight, watertight or other enclosures.

The following are some materials that can be used in enclosure construction and their advantages.

- Extruded aluminum – more easily modified, lighter than steel and not susceptible to rusting. Moderately costly however.

- Stainless steel – corrosion resistant and improve performance when given powder-paint finishing. Costly.

- ABS Plastic – shiny surface that is impervious, amplifiable, temperature-independent impact resistance, resistant to concentrated acids and alkalis as well as vegetable and mineral oils. Used in temperatures from 0-125°F, NEMA 4X-rated. However degradable with acetone and flammable at higher temperatures.

- Polycarbonate plastic – high impact resistance, larger temp range of -31 – 180°F, dimensional and UV stability, fire retention 4x-rated, fairly resistance to acidic environments. However, cannot withstand exposure to strong organic solvents or alkalis.

- Polyester plastic – lightweight, high impact, chemical and moisture resistance, excellent insulation properties, large temp range: -40 – 248°F. Impact resistance reduced in cold weather though affected by direct sunlight.

- PVC Plastic – good insulation, fire safe, durable, long lifecycle, high impact resistance, cost-efficient, recyclable, cheap UV degradation-resistance, easy processing for customization. Limited thermal capacity and sensitive to temps exceeding 70°C.

- Fiberglass – large temperature range: -31 – 300°F, available in different colors, electrical properties and dimensional stability, high moisture and chemical resistance. Easily scratched and could produce toxic fumes however. Low impact resistance and expensive in non-corrosive locations.

6. Size

In selecting the size of your enclosure, you should consider where the enclosure equipment will be mounted, as well as any specific enclosure location demands that must be met.