Table of Contents

Knob and tube wiring, a once-popular type of electrical installation, holds historical importance that you may be unaware of. This blog post walks you through the complexities of knob and tube wiring, its ramifications, risks, and why modern solutions are so important today.

Knob and tube electrical wiring dates back to the late nineteenth century, when the United States experienced rapid industrialization. By the 1880s, this technology had become widely accepted as a standard method of distributing electricity in households.

This technique gained popularity because it was inexpensive and used materials that were easily available at the time. Knob and tube wiring enabled the safe flow of electrical current, particularly in the absence of more modern insulating technology.

Despite its inventiveness at the time, by the mid-twentieth century, tube and knob electrical wiring became obsolete, mostly due to the progress of electrical technology that led to safer, more efficient wiring systems.

What Is Knob and Tube Wiring?

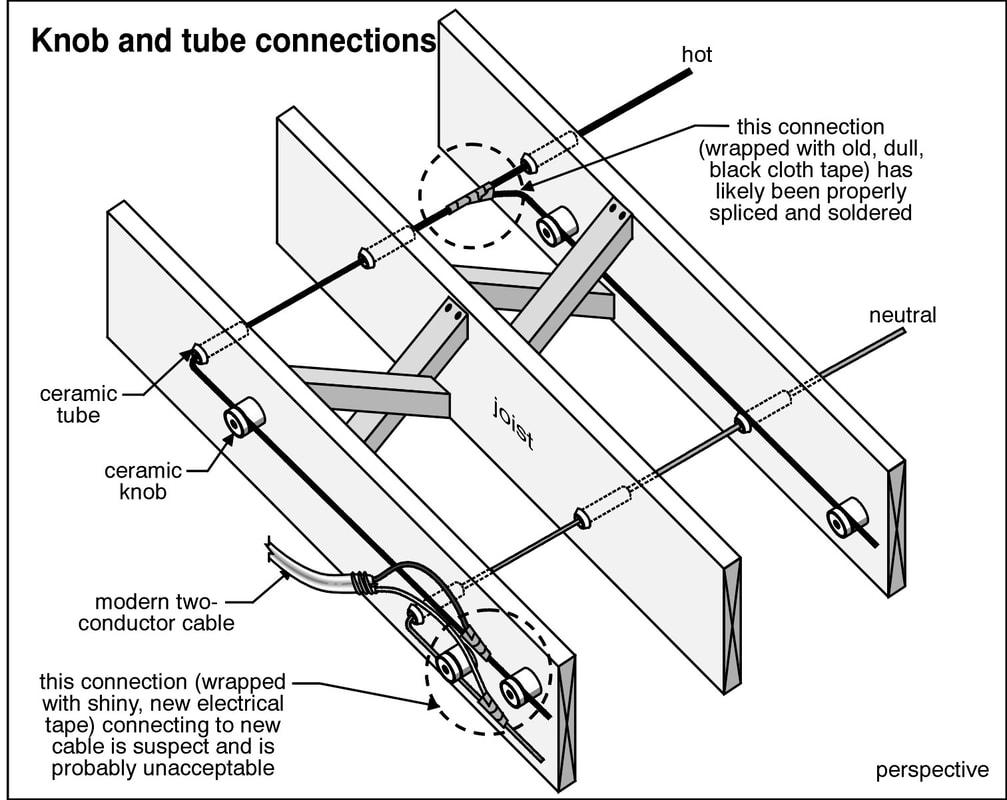

Knob and tube wiring consists of insulated copper wires that run through wooden beams. These wires are held in place using porcelain knobs, while tubes are used to direct the wiring through structural elements, such as walls and ceilings. Visually, it often features open, exposed wiring, by which its unique structure can be identified.

How Do Knob and Tube Wiring Look?

To determine knob and tube wiring, search for:

- Porcelain Knobs: These are little porcelain bits attached to wall studs or beams.

- Porcelain Tubes: These are hollow ceramic cylinders that convey wires through walls.

- Exposed Wires: Unlike modern installations, which are wrapped in protective sheathing, exposed wires are often apparent.

Understanding the visual characteristics of knob and tube wiring might help you recognize it during home inspections.

How Does Knob and Tube Wiring Work?

Knob and tube electrical wiring, like most modern wiring systems, uses alternating current (AC). The copper cables conduct electricity. The porcelain knobs act as insulators, preventing collisions with wooden buildings. The system is quite simple! However, it lacks modern wiring’s safety features, most notably the grounding system, which helps to avoid potential risks.

Knob and Tube Wiring Diagram

Knob and Tube Wiring vs. Modern Wiring: What is the Difference?

While knob and tube electrical wiring and current wire systems serve the same core purpose of delivering electricity, there are numerous important distinctions between them:

- Safety Features: Modern wiring contains specialized grounding wires. This feature is an important safety feature that reduces the risk of electrical shocks and fires, which is missing in the knob and tube wiring.

- Load Capacity: Knob and tube electrical wiring is rated for a maximum of 30 amps. However, modern systems can handle much higher loads thanks to stronger wire materials and insulating techniques.

- Compliance: Most building codes now severely restrict or prohibit the installation of knob and tube wiring due to safety issues, whereas modern wiring follows tight criteria that prioritize electrical safety.

Is Knob and Tube Wiring Safe?

While it does have some advantages, such as being relatively easy to repair, there are several safety concerns you should consider. It’s essential to have a qualified electrician assess your home. They can evaluate its condition and advise whether updating knob and tube wiring is required to ensure your home’s safety.

Why is Knob and Tube Wiring Dangerous?

If you are living in a home built in the early to mid-20th century, you might have come across knob and tube wiring. It’s essential to understand that while this kind of wiring was once a common practice, it can pose significant safety risks today.

- Shock Hazard: Knob and tube electrical wiring lack a designated ground line. It puts you in greater danger of electrical shocks when operating products. In contrast, contemporary wiring has numerous levels of protection against such events.

- Fire Hazard: One of the most concerning issues linked with knob and tube wiring is the possibility of Electrical fires. Over time, the insulation around the wires may deteriorate, increasing the danger of overheating and short circuits.

- Insurance Concerns: It is challenging to get knob and tube wiring insurance. Many insurance companies refuse to cover properties that still use knob and tube wiring or charge higher prices. This poses a considerable financial risk and might impede the selling of properties with obsolete electrical systems.

- Not Fit for Modern Loads: Today’s houses rely on a variety of high-energy appliances, such as refrigerators and entertainment systems, that require more power than tube and knob wiring can safely handle. Attempting to use such devices with an older system may result in severe overloads.

Is it Challenging to Obtain Knob and Tube Wiring Insurance for Older Homes?

Getting insurance for homes with knob and tube wiring can be difficult. In many circumstances, insurers may require an examination before issuing coverage. If they identify older wiring, they may deny coverage entirely or impose additional conditions and exclusions.

Addressing this wiring is frequently a required step if you are seeking financial security as a homeowner.

What is the Right Time for Replacing Knob and Tube Electrical Wiring?

Monitoring your knob and tube wiring is critical to your safety. Key signs of the necessity for replacement are:

- Brittle Insulation: The rubber insulation that surrounds the wires can become brittle and deteriorate over time.

- Frying: Signs of fraying or overheating indicate the presence of loose connections, which increases the risk of fire.

If you detect any of these indicators, you should check with a certified electrician for changing knob and tube wiring.

What is the Cost of Replacing Knob and Tube Wiring?

The financial outlay necessary for removal of knob and tube wiring varies greatly depending on home size and complexity. On average, you can anticipate to pay between $12,000 and $36,600, which equates to around $10 to $20 per square foot.

While this may appear to be a large expense, it may be justified given the safety benefits and potential insurance implications.

How Can You Replace the Knob and Tube Wiring?

Replacing knob and tube wiring is not a do-it-yourself project; it requires technical competence. Here is a summary of the essential steps involved

- Evolution: A professional electrician will thoroughly inspect and assess your home’s electrical system, determining the integrity and safety of existing wiring.

- Electrical Plan: Following the evaluation, the electrician will create an electrical plan and design specific to your home’s layout, energy requirements, and local electrical codes.

- Acquisition of Permit: To comply with requirements, your local building department may need you to seek a permit before undertaking any work.

- Cutting of Power: Shutting off power to the affected areas provides a safe working environment for the electricians.

- Old Wiring Removal: Electricians will carefully disassemble the old electrical wiring knob and tube, including all accompanying knobs and tubes.

- New Wiring Installation: Modern electrical systems will be built in line with approved plans, ensuring compliance with safety regulations.

- Upgrade of Electrical Panel: Your electrical panel may need to be upgraded to suit the increasing load needs of today’s appliances.

- Test and Inspection: Following installation, the new wire will be thoroughly tested to verify it fulfills safety requirements.

- Final Examination: A final inspection by a building inspector will check that all work meets applicable codes.

When is the Time to Contact a Professional?

If you suspect your home contains old knob and tube wiring, or if you are experiencing electrical problems, you should contact a certified electrician. Their experience is crucial in recognizing potential hazards, particularly prior to any big renovations.

Knob and tube electrical wiring represent a period of innovation. Still, it is also a ticking time bomb of safety hazards. It is critical to avoid DIY solutions and instead hire a professional to safeguard your home’s safety and security.

Ready to make your home safer? D&F Liquidators has all the electrical supplies you need to Replace the Knob and Tube Wiring. Explore our collection today and ensure your home can safely handle your electrical needs.

Frequently Asked Questions (FAQs)

When were knob and tube wirings used?

Knob and tube wiring was commonly used from the late 1800s to the mid-1900s. It was a popular choice for electrical systems in homes and buildings because it was a relatively simple and cost-effective method for wiring.

When knob and tube wiring usage was stopped?

The use of knob and tube wiring began to decline in the 1940s as newer, safer electrical wiring methods gained popularity. By the 1950s and 1960s, it was largely phased out in favor of more modern wiring systems.

Is knob and tube wiring removal challenging?

Removing old knob and tube wiring can be complex and labor-intensive, often requiring professional assistance. The difficulty arises from the need to safely disconnect it from your electrical system and possibly upgrade to modern wiring standards to ensure safety.

Is it legal to have knob and tube electrical wiring?

The legality of knob and tube wiring depends on local building codes and regulations. In some areas, it may be permitted as long as it is in good condition and meets safety codes. However, many insurers will not cover homes with this type of wiring due to potential fire hazards.

Can you use knob and tube wiring with circuit breakers?

Knob and tube electrical wiring can be used with circuit breakers. But, it’s essential to ensure that the installation is done correctly to avoid potential risks. Ideally, a licensed electrician should inspect the wiring and make any necessary upgrades to ensure safety.

How to identify knob and tube wiring?

To identify knob and tube wiring, look for ceramic knob supports and tubes that encase the wires. It typically has two separate cables – one for the hotline and one for the neutral line. It is often found in older homes. If you are unsure, consulting an electrician is a wise choice.

How is cloth wiring different from knob and tube electrical wiring?

Cloth wiring, which became popular in the early to mid-1900s, consists of insulated copper wiring wrapped in a protective cloth covering. Unlike tube and knob wiring, cloth wiring does not use knobs or tubes for support but may be found in similar installations.

Both types are no longer up to current safety standards. However, cloth wiring is sometimes seen as a bit more resilient than knob and tube wiring.