Table of Contents

When you think about the cables that power your environment, you may reflect upon the typical options—thick wires and plastic sheathing—which aren’t particularly exciting. But enter braided wire, a true game-changer that brings a unique twist—quite literally—to the way you connect and transmit signals.

This article delves into the intricacies of braided wire, throwing light on its benefits, applications, and why it’s becoming so popular in a variety of sectors. Prepare to uncover the complexities of this intriguing subject!

What is Braided Wire?

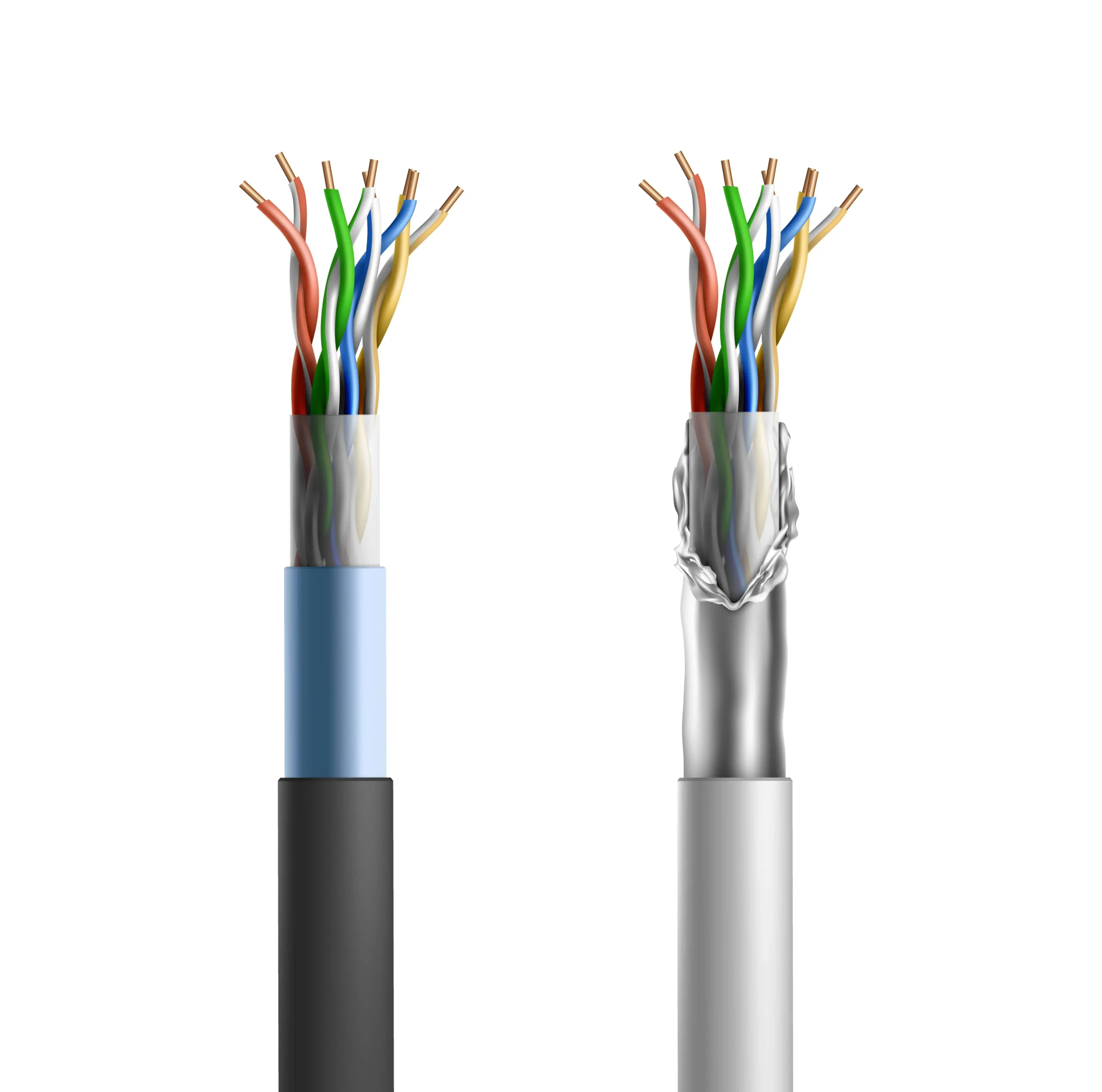

Braided wire is a specialized type of cable shielding designed primarily to guard against electromagnetic interference (EMI) and enhance the mechanical strength and flexibility of cables. Its structure consists of numerous fine wires intricately woven into a mesh that encases the conductor, with an insulating outer layer for additional protection.

Common materials used to make a braided cable include tinned copper and silver-plated copper. However, options like nickel-plated copper, gold-plated variations, pure silver, pure nickel, gold alloys, Monel, and bronze can also be customized for specific uses.

Why is Braided Electrical Wire Important?

The significance of braided wire lies in its ability to prevent EMI from disrupting signals—crucial in today’s tech-heavy world filled with devices emitting radio waves or other frequencies.

This shielding ensures reliable signal strength while also adding resilience through its flexible design that accommodates frequent bending without damage. Moreover, copper braided wire facilitates a low-resistance ground path suitable for short runs in various applications.

What are the Benefits of Braided Wires?

Braided cables are becoming increasingly popular, and for good reason. Here’s why you should consider making the switch:

-

Durability

Braided cables are designed to last. Their distinctive shape makes them resistant to breaking and damage, even after years of rigorous usage.

-

Noise Reduction

Braided wires are excellent at minimizing electromagnetic interference. When you use them to connect your audio equipment, you get a cleaner signal with a lower noise floor, which improves your sound quality.

-

Aesthetics

These cables are available in a range of colors and provide a stylish touch to any audio system. So, braided speaker wire provides a utilitarian purpose while also adding a personal touch to your environment.

-

Tangle-free Design

Say goodbye to knots. Braided cables are intended to avoid tangling, making them easier to handle during setup and pack-down. This function saves you time and frustration.

-

Increased Rigidity

These cables seem more sturdy than typical rubber cables due to their braided structure. They hold their form better and are less likely to fray at the connecting areas.

What are the Common Uses of Braided Cable?

Braided wire has an essential function in many sectors, demonstrating its adaptability. In aircraft, it is used to provide critical EMI shielding for sensors and radar systems, as well as in wire harnesses and ground straps. Its flexibility and durability make it useful in the automobile industry.

It is used in battery cables and grounding straps and to provide EMI shielding for advanced car electronics that operate in harsh environments such as heat and vibration. Furthermore, biocompatible stainless steel alloy braided wire is used in tiny medical devices such as implanted probes and catheters to provide a flawless connection with external electronics.

To summarize, braided cable is more than simply a stylish twist on traditional cables! It is a significant innovation that improves performance, durability, and aesthetics in a variety of applications. Its unusual structure not only protects against electromagnetic interference but also provides unparalleled flexibility and durability.

Now that you’ve gained all of this knowledge, why not take the plunge? Consider switching to braided wires for your audio equipment or any other tech setup to see the difference first-hand!

Discover durable braided cables at D&F Liquidators for all your needs. From audio to industrial applications, we have the perfect solution.

Frequently Asked Questions (FAQs)

What is stranded cable?

Stranded cable is made up of many wires twisted together within each conductor. It provides greater flexibility than solid cables. This versatility makes it excellent for applications that need bending and shaping. However, because stranded cable has a higher signal loss, it is better suited for shorter lengths rather than lengthy spans.

What is the difference between braided wire and stranded wire?

Braided and stranded wires differ primarily in their manufacturing and protective properties. Both are flexible, but the braided wire is more durable, withstanding abrasion, heat, moisture, and other environmental conditions. It is made up of many strands that have been wrapped in insulation for further protection.

Stranded wire, on the other hand, lacks insulation and is covered solely by an essential jacket. Braided wire is more resilient than stranded wire because of its layered construction.

Which is more expensive: stranded wire or braided wire?

The braided cable typically costs more than stranded wire due to the elaborate production process, which entails weaving numerous wire strands together, making it more laborious.

Which cable is best for electrical wiring?

Copper and aluminum are the most often used materials for electrical wire cables. Copper cables are the ideal option because of their better conductivity and longevity. Additionally, selecting multi-stranded wires over single-stranded ones can improve flexibility and lower the danger of breaking.